This is an old revision of the document!

Pressure Advance

An easy explanation of Pressure Advance (also known as Linear Advance) is this opening to this article by Prusa Research:

Linear Advance (LA) is a technology that predicts the pressure build-up in the extruder when printing at higher speeds. The firmware of the printer uses that prediction to decrease the amount of filament extruded just before stopping and decelerating, which prevents blobs or artifacts at the sharp corners.

Klipper's docs demonstrate this practically further:

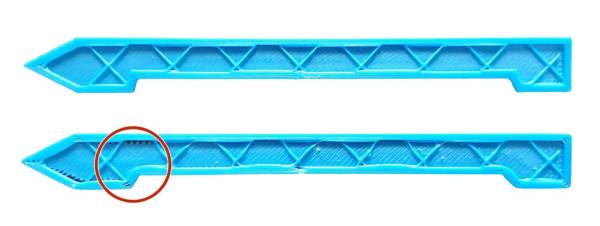

Pressure advance does two useful things - it reduces ooze during non-extrude moves and it reduces blobbing during cornering. This guide uses the second feature (reducing blobbing during cornering) as a mechanism for tuning.

In order to calibrate pressure advance the printer must be configured and operational as the tuning test involves printing and inspecting a test object.

For detailed information as to how pressure advance operates read https://www.klipper3d.org/Kinematics.html#pressure-advance

For instructions about tuning pressure advance see Orca's calibration tool documented at https://github.com/SoftFever/OrcaSlicer/wiki/pressure-advance-calib

Pressure Advance and Nozzle Size

Larger nozzles increase the flow rate by a cubic exponential. A 0.6mm nozzle has about twice the flow rate as a 0.4mm nozzle. As the nozzle size increases Klipper generally requires a lower pressure advance for the same material. The rule of thumb being around two-thirds the value, when switching from a 0.4mm to a 0.6mm nozzle for example, but it must be recalibrated for each filament. Larger nozzles increase the flow rate, which changes the dynamics of extrusion pressure and requires adjustments to other settings like line width, print speed, and temperature to maintain print quality.